This compact solution automates both weighing, bundling and banding together in one machine.

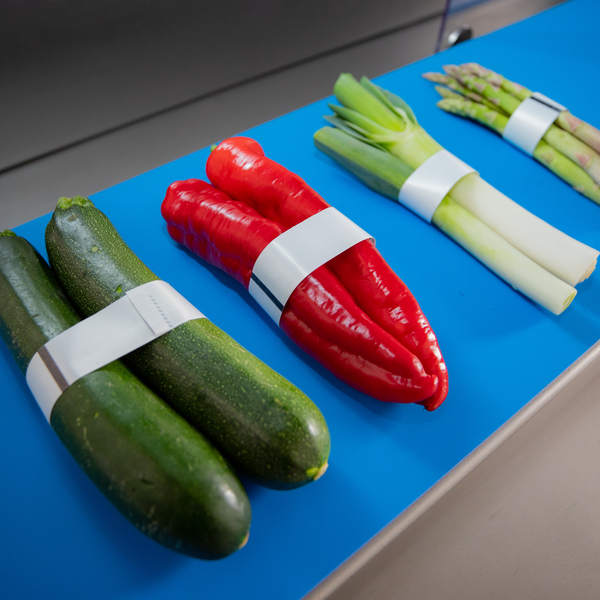

The machine is suitable for processing a large variety of produce, such as zucchini, sweet pointed peppers, leeks, asparagus, carrots and rhubarb, and more.

How it works

The products are manually inserted into the 10 weighing units. A combination of these 10 products is made based on the preset weight. Naturally, the introduced products are handled carefully so that quality is guaranteed.

The banding machine creates a bundle by bringing the loose products together with a band. The bundle is transported by a conveyor belt which, if desired, can be connected to a turntable.

Capacity

Our weighing and banding machine has a capacity of up to 24 packages per minute per line. Depending on the desired production speed within your business process, multiple lines can be placed next to each other, increasing the overall capacity. Here there is the possibility of connecting a general conveyor belt to this, which then discharges to a rotary table. In this way, all bundles, from all machines, arrive at one central location.

The weighing and banding machine can also be connected directly to a flow pack line. With this assembly, a total capacity of up to as many as 4,000 packages per hour can be achieved.