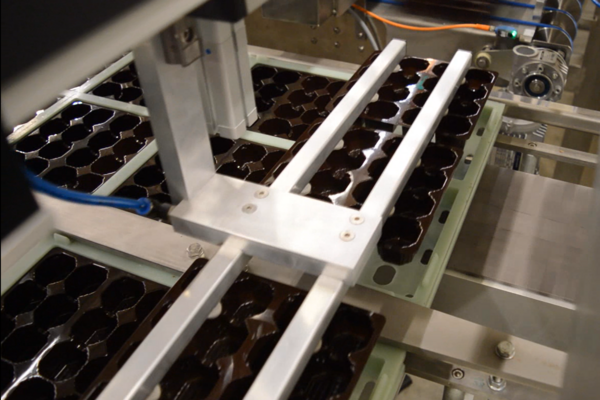

For use in a production environment where hygiene is essential, Freshtech Solutions has developed food-safe and hygienic stainless steel conveyor belts. This conveyor belt can be used for all types of goods, both loose bulk goods and packaged goods.

The conveyor belt has round surfaces (frame) and an adjustable side guide. The adjustable side guide ensures that products of different sizes are transported safely. The conveyor belt has an open structure and is easy to disassemble and therefore easy to clean.

The best solution for your application

The hygienic conveyor belts are available in various versions. Think of a stainless steel motor, made of stainless steel 304 or 316 with a closed or open conveyor belt, removable side guide and IP66 control box.

Depending on your wishes, our experts make your design possible. In this way you choose a conveyor belt that best suits your production process and you realize a maximum output.

Curious about how the multifunctional conveyor belt fits into your production environment? Please contact us to discuss the possibilities.