09 Dec In conversation with Michel: a complex but more complete future

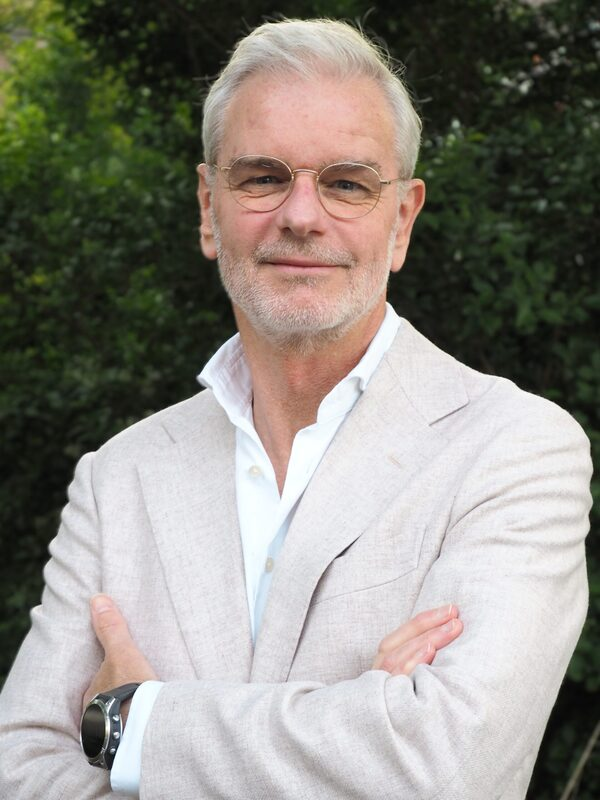

From as early as 2008, Freshtech has been designing and developing solutions that are not standard, but that deliver the specific optimization the client is looking for. How does Freshtech accomplish that? How does Freshtech reflect on the past years? And where do the opportunities and focus lie in the coming years? Together with Michel Koppert, director of Freshtech Solutions, we look back.

How did you experience the market in recent years?

Currently, labor is expensive. Labor is scarce and well-qualified labor is even scarcer. As a result, the demand for automation and optimization of production processes is increasing. Optimized and automated processes ultimately lead to reduced pressure on HR for finding the right workforce and also to maximize output. In addition, it has not escaped anyone’s attention that inflation is skyrocketing. A cost increase that cannot always be charged to the end consumer. Therefore, to keep margins attractive, many organizations are looking for process optimizations, in the form of automation. In this, automation should reduce stress in (labor) costs.

Another important factor that makes organizations want to automate is product and/or process sustainability. Awareness of sustainability and responsibility has intensified in recent years. Freshtech likes to think along with this. Through successful projects we have developed a solution that is somewhat standardized and can be used in multiple environments; the banding machine. The banding machine immediately puts an end to unnecessary packaging with plastic in the AGF sector.

Where will Freshtech’s focus be in the coming years?

In particular, we want to contribute to a productivity boost, better safety on the workplace and more sustainable production processes. For many organizations, there is still much to be gained there. Freshtech maps out the entire production process and, with the right objectives in mind, we determine which solutions are most effective. We look at factors such as cost-effectiveness, energy consumption, safety and ease of operation. This is all reflected in the design. The solutions thus become more complex but also more complete due to the many requirements and possibilities. That’s what makes our job so interesting. With a helicopter view we look at the complete solution, so it delivers above and beyond customer expectations. The next coming years will be particularly interesting. How can we make processes and products not only sustainable, but also circular? How do we minimize waste in the process? How do we effectively deploy and use raw materials and energy? How to effectively link machines and develop a flow in production processes?

For Freshtech, it is interesting to learn how each industry deals with this and how we deal with this ourselves. We are currently working on some great innovative projects, so stay tuned!