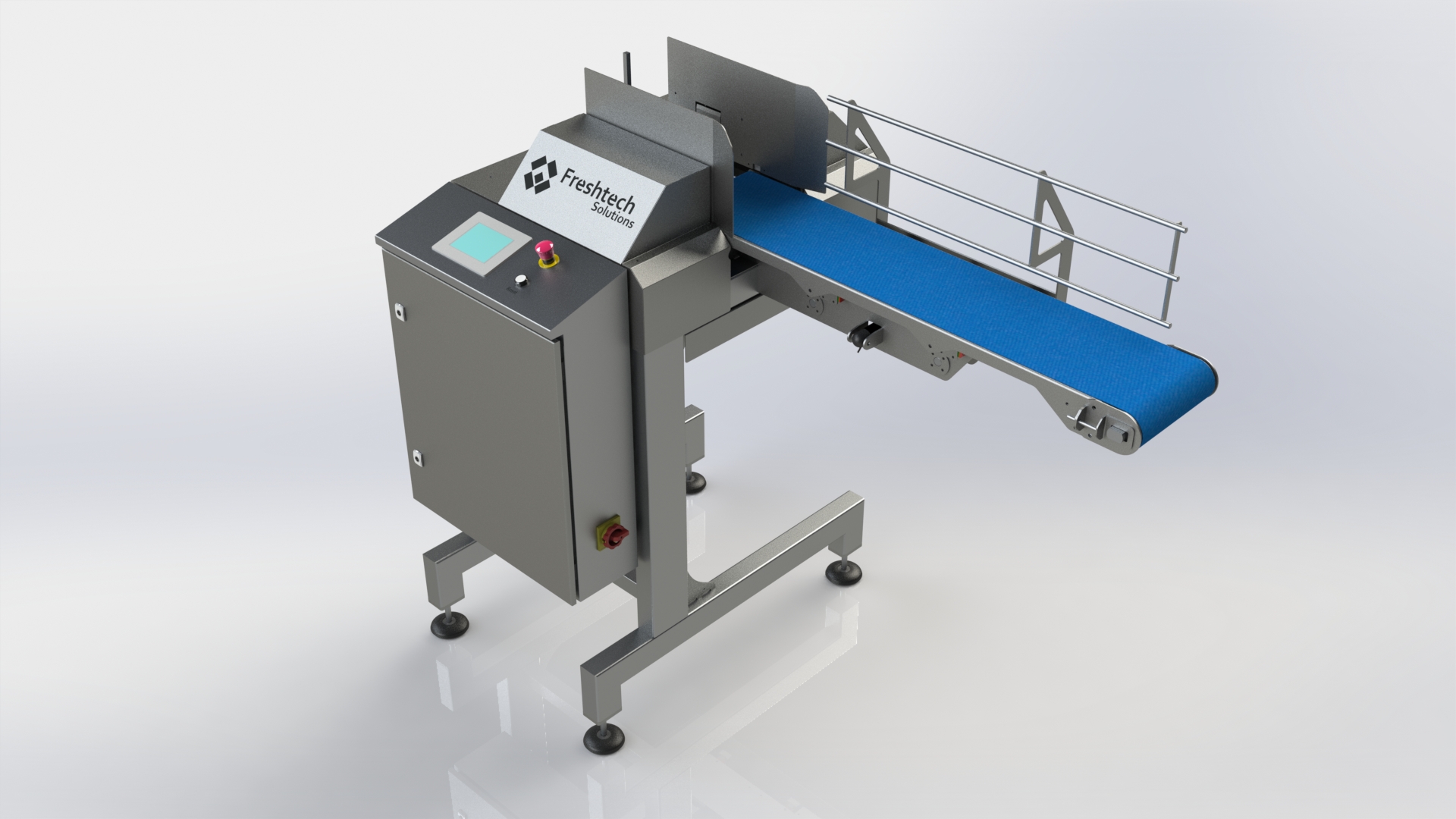

Universal denester

The functional denester can destack almost any type of tray, plastic or cardboard trays, various shapes at a speed of up to 120 trays per minute, making the machine unique within its segment. The changing of trays occurs fully automatically with a setup time of less than 1 minute. The machine can be operated through a 7-inch touchscreen, displaying all current data in a user-friendly manner. The machine has been a proven solution for many years within the entire fresh produce and food sector.

Freshtech Solutions focuses on efficiency, cost savings and user-friendly machines, such as the universal tray denester. This often requires customization that is entirely focused on the specific wishes of the user. Sometimes, the innovative solutions are so widely applicable that they become the new standard. The advantage of a new standard is the cost saving of the regular customization procedure. Herewith we process our expertise in a standard solution. Our universal denester is an excellent example of how we build our machinery.

Multifunctional denester

The universal tray denester from Freshtech was designed during the development of an entire logistic system. Due to the possibilities for several production processes the demand for this machine rise at Freshtech Solutions. We believe in the concept of customization. Why? Every production process is different and has its own circumstances, requests and demands. The concept of customization, specifically for denesters, means that the basic functionality is the same for several production lines and sectors, therefore a standard can be developed.

The universal denester has found its way within the fresh produce and food sector. Connected to a flowpacker, conveyor belt or production line, the universal denester can destack various trays up to 120 pieces per minute. The denester characterizes not only by the huge variety of scales, trays, cups and blisters, but also the sizes and materials can differ. We provide the most flexible machine in the market, where efficiency and effectiveness are leading.

Time and cost saving

The denester is a machine that grows with your organization. Are you dealing with making packaging more sustainable or changing the number of products per packaging? Multiple products with different packaging requirements? That is not a problem at all! The universal denester is operated by means of a user-friendly touchscreen display. It allows you to easily pre-program, edit and select up to 32 tray sizes for denesting. All you need to do is place a stock buffer of trays on the conveyor belt and the machine does its work. Fast and efficient so that you have time for other activities.

- Destacking up to 120 pieces per minute

- Setup time less than 60 seconds

- Pre-program up to 32 scale formats

- Plastic, pulp, cardboard, and paper

Changeover times

We hear you thinking: what about the conversion and changeover times? Conversion costs and changeover times are subjects of the past. The Freshtech Solutions denester is there to make the process more efficient, not more difficult. With one touch on the touchscreen display the machine adjust itself fully automatically within one minute to the newly selected tray.

Benefits

- Integration into existing processes

- Customization to your process is, of course, possible

- Time savings and reduction of labor costs

- Proven solution in the AGF and food sector

- A complete logistics system

- User-friendly control

Curious about the possibilities?

We understand that a standard solution is not always standard! That is why we always first look at your process of denesting, the tray, the possibilities and your wishes. Quality, care and attention are our top priorities! Curious about the possibilities? Please don’t hesitate to contact us!

Would you like to know where more efficiency can be achieved in your company? Call +31 (0)174 520 414 or email info@freshtech.nl to make an appointment without obligation.